Have you ever wondered why wholecut oxfords are more expensive and often cost more than other models of the oxford family? You might think to yourself that it is odd, assuming that because it is one piece, which when using logical deduction would/should involve less work. But the contrary is actually true. It involves more work and I will explain why below.

The first stage of quality is defined by the process of cutting the leather, known as ‘clicking’. That is the basis for upper leather quality and really what separates the novices from the experts. The higher in price you go, the better that leather is cut (in theory, where reality is often different these days though). You are paying for that attention to detail, that fine eye, and a steady hand. The art of cutting around the flaws while at the same time maximizing the use of the hide. This process is a form of art, to be quite honest, and takes skill to do so well. It really is what separates the great shoe brands from the rest.

When making a wholecut shoe, you are cutting one large piece of the hide. Even when cutting into 1st-grade leather it is not as simple as just slapping down the pattern and cutting around it. You have to mark that leather, find the flaws, and then make sure that when you cut the whoelcut piece, you are cutting the prime parts of the hide where there are little to no flaws. It is not as easy as one might think, especially when cutting larger sizes. At the same time, you are also cutting only the prime parts of the leather, which costs more.

The lower sub-grades of a hide are less desirable and are usually saved for heel counters, piping, excess leather used for the underside when lasting, etc. Skilled cutters can utilize the poorer areas to cut full brogues and thus save money. And that is why it is an art form and why wholecuts oxfords are more expensive. There is no hiding a flaw on a wholecut oxford. But on any brogued shoe, flaws can be hidden through intelligent cutting. So you pay the premium for that supposed flawless leather. And you should pay less for models that are able to utilize lower grades of leather.

The second reason that wholecut oxfords are more expensive is that they are also harder to make due to the lack of tension that they possess, in contrast to a 5-piece oxford model. This will be easier to understand if you are really good at physics or have lasted a shoe by hand but the reality is that when lasting a whole cut oxford, when you pull one end, the other side follows and that creates the challenge.

That might seem trivial but it is not as trivial as one might think without truly understanding the difference in tension between a single piece and a piece with seams. You see, the seams allow you to pull one side while the other side stays more put as the seams give it more leeway. When it is just one piece, there is no leeway. This lack of leeway makes it more difficult to last the upper and not leave air pockets of space.

Lasting a wholecut oxford upper is more challenging because if not done properly you will be left with a lot of excess space in the vamp which then leads to excess creasing. The key to lasting a whole cut oxford in the lasting machine is actually little by little, pulling one side, then the other, then again on the first side, then again on the 2nd side, until you have it even and firmly placed on the vamp. If you just pull both sides at the same time with one large pull, you leave room for excess space being left over. Those extra steps take time and time costs money. Lastly, a whoelcut oxford should also stay on the last longer to ensure it forms to the shape. All delays and extra steps add to the price of a shoe.

So when you are looking to get a whole cut oxford and cannot understand why it is more expensive, think of this post. And for the makers that charge the same as their other shoes, well you can look at that two ways. They are either overpricing their other shoes and/or underpricing their whole cut models and absorbing that cost for you. But without a doubt, they are not the same cost price.

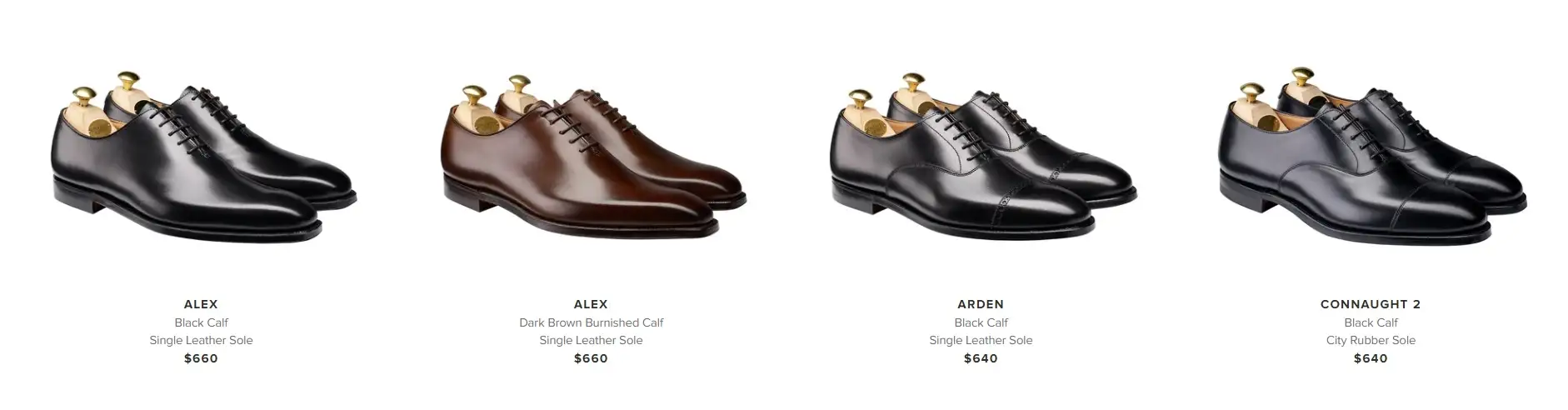

All photographs are courtesy of Crockett & Jones

—Justin FitzPatrick, The Shoe Snob

Shop · Marketplace · J.FitzPatrick · Patreon

Nice article, but it seems counterintuitive to me that whole-cuts should be cheaper, but I guess I can see why some may think otherwise.

Thanks JHS. They shouldn’t be, but I know how many people’s mind work so know that when they see one piece then think less work, hence me breaking it down

Thanks again Justin, I always thought the opposite, but I’m glad you broke down the actual science of it.

-Much Appreciated-

Zohair Merchant

My pleasure my friend! Thanks for reading

I love this post! The art of wholecut shoemaking should be more appreciated. Indeed properly lasted wholecut and the leather quality really set great apart from the good and so-so. Thanks Justin~

Thanks Kyle and for the great photo!

Thanks for the nice little article Justin.

And all you said is without even mentioning seamless wholecuts, for which I can’t even start to imagine how skilled the shoemaker must be to give shape to a single piece of leather without even cutting it! 😮

My pleasure Christopher and thanks for saying so 😉 appreciate your support!

The tension when pulling parts of the leather makes a lot of sense, now that I think about it!

Thanks for this post, Justin.

Question: could this mean that breaking in for wholecuts will be harder/longer when stiffer leather and, au contraire, easier for softer leather, compared to 5-piece leather shoe?

Hey Steve, actually wholecuts are always easier to break in and usually full/semi brogues are usually more difficult. The seams in this case actually create more rigidity

You re right Justin ! Excellent démonstration ✔️

Thank you!

Great article. So the tension you speak of must be important in lasting a faux brogue as well. Is that why some companies, like Edward Greene do this on a plain toe Oxford instead of a Wholecut? And also why a few brands make what I call “nearly wholecuts” with a patch on the back or across the top line on the back? Is this to relieve / balance the tension?

Thanks John! And yes, the issue is when the facing and vamp are all one piece. That is where the tension occurs, underneath the lacing. If there is a seam there, then it relieves it and allows for easy lasting, but if it is all one piece, due to the shape of lasts/insteps, if you pull one side, the other follows. So it is hard to create a perfect lasting with little to no excess air between the upper and the last