In this guide to shoe pricing, we will take a look at the variable components that make up a shoe’s price and how simple changes can affect the outcome. There is a lot of confusion in the consumer’s eyes on what you should expect from a pair of shoes and I was hoping to clear that up for some of you. It is important to know what you will get from the price you will pay for a pair of shoes. So let’s break it down.

I have stated this before and I will do so here again but there are three main components that create the dress shoe’s price and those are:

The Variable Components

Leather Used (or not used)

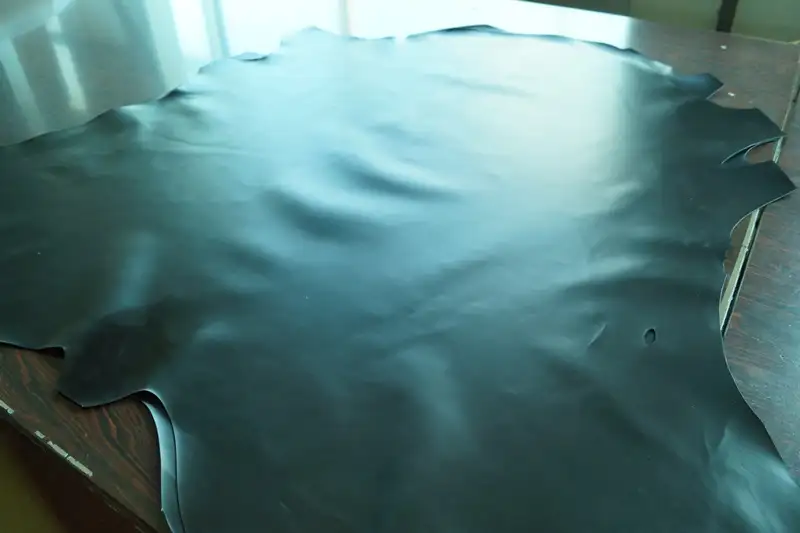

This is what really separates many of the price points of shoes. When you buy leather you buy it in hides but it is priced in either meters or square feet. One large hide can cut between 6-8 pairs of shoes (depending on the size of course. They are not always large). Let’s break this down now and see how vastly this can vary. An expensive leather could be €130 per square meter. A common hide is about 1 meter wide by 1.5 meters long, so its value would be €195 per hide. Let’s assume this hide cuts 6 pairs.

- If you cut one pair from that hide this shoe has €195 worth of leather in it (not counting the other components of the shoe like sole leather, heel block, etc), but you wasted ⅚’s of the leather which you are still charging the consumer.

- If you cut 3 pairs from that hide, the shoes have €65 worth of leather in them, but you wasted half of the leather that you are passing onto the consumer in the shoe’s price.

- If you cut 6 pairs from that hide, each pair of shoes has €32.50 worth of leather and no wastage.

A factory making the same quality of shoe but either cutting 1 or 6 pairs can have an extremely different retail price. It will most likely also have an extremely different-looking shoe due to where the pieces were cut on the hide.

For example, it was once reported that a very famous shoemaker would buy 3rd-grade leather only and cut one pair from each hide. From a 3rd-grade hide, you can at least cut ‘one perfect pair.’ They were smart in doing this as they saved money in buying the leather in bulk and then most likely used wastage for other things like factory shop shoes or sale websites etc. So even if the hide cost €80, the shoe was valued at €80 worth of leather, despite really only using ⅙ of the hide.

The Cost of Labor

Each country pays its laborers differently and in each city, you get a different wage too. For example, if your factory is closer to Florence, Italy, you might get a higher wage than a factory that is in Marche as the cost of living will be different.

For example, in Almansa, Spain an apartment of 3 bedrooms costs around €500/month. In Kettering, UK (where Gaziano & Girling are), that same apartment might run you around 700-1000 GBP. Therefore, G&G will most likely pay their workers more than a factory in Almansa. Get the drift?

Now think about how much laborers make in places like Vietnam, China, or other countries that make shoes but have low-wage labor. Therefore the same quality of shoes can be more expensive based on its location of production, and cheaper too, if made in a place with a low cost of living. Hence why Spain generally has shoes of lower price points than England. And shoes made in Asia that are hand welted are ⅓ of the price or less, of hand welted shoes made in Europe.

This doesn’t even take into account taxation. Did you know that in Italy if a factory worker earns €1000/month, the factory has to pay the government another €1000/month for that same worker in “taxes”? They pay 100% taxation. This is insane but very real and that adds to the cost of everything produced in Italy. Something most of you probably do not know. That will be similar throughout Europe.

Shoe Pricing Markup

This is naturally the most important component and really what you are paying for. In the shoe industry, the common markup is between 2.5x-3x the cost/wholesale price. Therefore, the greater the cost to make the shoe, the greater the value of the markup you are paying. For example, if a shoe costs €100 to make and there is a 3x markup, you are paying €200 in markup. If the shoe costs €150, you are paying €300 assuming a 3x markup. And so it goes on.

Now, this is not so simple either as some brands/companies will have wholesale markups too. For example, if you are a brand and intend to sell to other retailers, you will need to add a small wholesale markup to the price you pay for the shoes. So if you pay the factory €100, you will most likely wholesale those for €120-€130 and then add your 3x markup to get the retail price as the wholesaler will at least want a 2.7 mark up and you cannot undercut them and vice versa.

Markup can also be egotistical too. A country that feels their shoes superior might have a higher markup simply for the sake of the value of how they perceive their shoes to be with respect to another country. But the reality is that markup is usually created by brand value, history of the brand, demand of the brand, etc. Designer brands will easily have 7x-10x markups, sometimes even more.

Lastly, markup greatly depends on the micro-industry within the larger shoe industry. For example, that markup of 2.5-3x is for the welted shoe industry. You won’t believe what Blake-Stitched and glued shoes have as markups. And don’t even get me started on those designer shoes mentioned above that sell for +$1000 and most likely have an ex-factory price of $150 maximum (ex-factory means the price the factory sells at, not the actual ‘true cost’ which no one but the factory will know). That would be a 6.66x markup.

When creating a product you have two avenues to take: low volume/high margin or high volume/low margin. Think Nike as the latter and Hermes as the former. While Hermes is a large brand that sells worldwide, the units they will sell compared to Nike are relatively smaller. The issue with the ‘low volume/high margin’ brand is that the larger the company gets, the higher its prices go, as everything has to fit into that margin: Rent, wages, toilet paper, printing machines, accountants, etc. It all goes there.

There is a lot to a shoe’s price that you will never know or think about. I hope that this guide to shoe pricing has at least shed some light on the behind-the-scenes of how the price is initially built. There are many more factors that can come into account but these are the basic components that make up the shoe’s price.

If you have enjoyed this guide to shoe pricing, make sure to check out my other educational posts here.

—Justin FitzPatrick, The Shoe Snob

Shop · Marketplace · J.FitzPatrick · Patreon

Cost of living and cost of labor are two different things. Cost of labor has to do with the overall education and professional skill set in a locality. For example, US Federal Government locality rates are based on cost of labor, not cost of living. Houston is higher than almost everyone outside of the SF-OAK Bay area and New York, because of the space industry and the oil and gas industry. Meanwhile, Houston has relatively neutral cost of living compared to the US average.

I understand that they are different. But cost of living/housing/rent/real estate will all help to dictate cost of labor.

I am wondering why Church’s Shoes are so expensive now. I assume that they think they are a very premium company. Do you have any information on Church’s?

This might helps: https://theshoesnobblog.com/tag/churchs/

Interesting post and great to dig into the details of shoemaking costs.

PS. Thank you for not posting pictures of the outrageously expensive designer shoes 🙂

Thanks my friend, glad that you enjoyed 😉